How many employees does a fully automatic animal feed pellet production line plant with an annual output of 60,000 tons (25 tons per hour) feed?

1. How many employees does a fully automatic pellet production line plant with an annual output of 60,000 tons need?

According to a simple calculation method, Annual output=8H*300 days, then a fully automatic pellet production line with an annual output of 60,000 tons is a 25 tph feed pellet plant. Generally speaking, the feed production line of this output requires 7 employees, namely: 1 PLC staff, 2 feeding staff, 1 pelleting staff, and 3 packaging staff.

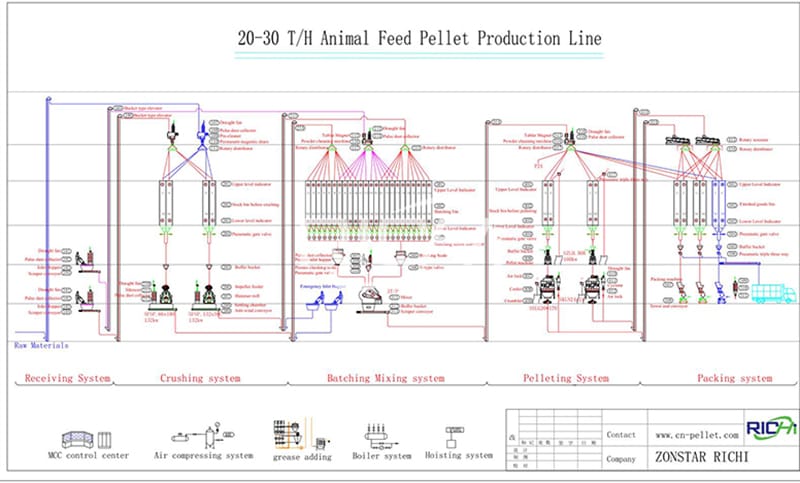

2. 25 tons per hour automatic animal feed pellet production processing line

(1) Production process

①Complete 25 tons per hour automatic poultry feed pellet production line process

Silos-Raw material receiving-Cleaning-Grinding-Raw material extrusion-Batching-Mixing-Pelleting-Cooling-Liquid Adding & Coating-Packaging-Conveying-Stacking

②Complete 25t/h automatic livestock feed pellet making plant process

Silos-Raw material receiving-Cleaning-Grinding-Raw material extrusion-Batching-Mixing-Pelleting-Cooling-Crumbling-Liquid Adding & Coating-Packaging-Conveying-Stacking

③Complete 25t/h automatic ruminant feed pellet production line processing flow

Cleaning-Grinding-Batching-Mixing-Liquid Adding & Coating-Pelleting-Cooling-Screening-Packaging

④25tph computer control feed plant for processing aquatic feed

Cleaning-Grinding-1st Dosing-Superfine grinding-2nd Dosing-Extrusion/Pelleting-Drying-Screening-Liquid Adding & Coating-Cooling-Packaging

⑤Complete 25 t/h automatic premix feed processing line plant(it has no pelleting section)

Cleaning-Grinding-Batching & Packaging-Mixing-Packaging

(2)Main animal feed manufacturing process machine of animal feed pellet plant

To ensure GMP cleaning is an important aspect. Different type of cleaner used for this purpose.

All transportations like bucket elevator, screw & chain conveyor etc. for conveying RM & Finished goods.

Raw materials need to be grinded as 225 m/microne perticle size by feed crusher for different type of feed.

Different R/M are mixed here with additives, oil/fat, medicines, etc. Good powder feed grinding mixing machine for animal feed ensure good quality.

Produce final pellet feed. A good pellet means "a complete feed" and a good feed pellet making machine can ensure that.

Extruded feeds are about 70-90° C. Animal pellet feed cooling machine bring down it at normal temperature (+4° max).

To ensure supply of quality and perfect size feed, screener plays a vital role. Uneven sizes screaned-out.

Ready pellet feed need to be packed. It can be manual or automatic bagging depends on requirement.

Regarding the cost of an automatic pellet production line with an annual output of 60,000 tons, and the investment price of a 25 tons per hour feed factory, please contact us directly for consultation. RICHI is a large animal feed mill manufacturer from China devoting in feed processing equipment , integrating the design, manufacturing, installation, mainly produce all sorts of feed pellet machines, crushing machine, mixing machine, lifting machine, cooling machine,etc and the complete animal feed pellet production line machinery. About more feed processing machines details, please Email: enquiry@richi-machine.com, Whatsapp/Cel: +86 185 7410 3366.

If you want to built one complete pellet production line in your country, pls send the inquiry to us. We will customized design according to your requirement.